As is well known, with good edge banding, one must also have good edge banding techniques. It is difficult to ensure a smooth and beautiful edge banding, a tight fit between the board and the edge banding strip, and a smooth transition between the board surface and the end face through traditional edge banding techniques. The new seamless edge banding technology can perfectly solve the above problems. As the name suggests, seamless edge banding technology means that no gaps can be seen in the edge banding of the board. The biggest highlight of seamless edge banding technology is its excellent edge banding effect, seamless integration between edge banding strips and panels, and high edge banding quality.There are currently two main seamless edge banding technologies on the market, namely laser edge banding and hot air edge banding.

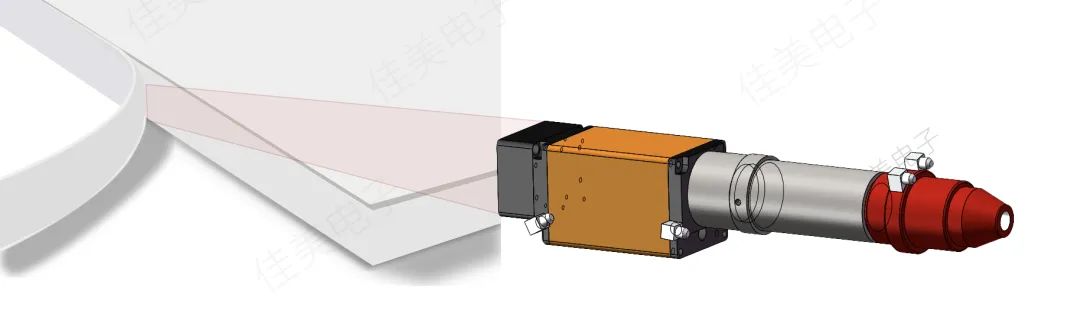

Laser edge banding does not require any additional adhesive system, and the edge banding tape used is coated with a special layer of polymerThe coating, when exposed to laser irradiation, melts and has strong bonding performance. It can perfectly combine the board and edge banding. At the same time, the polymer of the edge banding fills the gaps between the board and edge banding, as well as between edge banding and edge banding, achieving seamless and intact edge banding quality.

The principle of hot air edge sealing is to spray strong hot air into the reaction coating of the edge sealing material through the nozzle slot, in order to stimulate the adhesive on the layer to connect the edge sealing material with the board, and ultimately obtain a finished product without adhesive lines.

The laser edge banding process is very fast, without the need for heating and waiting, and the edge banding is produced immediately. Hot air edge sealing will be affected by the weather. If it is a rainy season, the moisture content in the compressed air is higher than usual, which will affect the heating quality. Not economical enough, only a portion of the sprayed hot air is absorbed by the back glue of the edge banding, and the rest is wasted.

In summary, both laser edge banding and hot air edge banding can achieve seamless adhesion between the edge banding strip and the workpiece, perfectly solving the traditional edge banding "glue line" problem. Compared to hot air edge banding technology, laser edge banding can achieve instant edge banding and the operation process is also faster and more convenient. Laser edge banding technology has improved some shortcomings of hot air edge banding technology, ensuring edge banding quality while making equipment more convenient and convenient to use. And it has improved the production efficiency of the factory, reduced the rate of product rejection, and ensured the accuracy of repeated production.

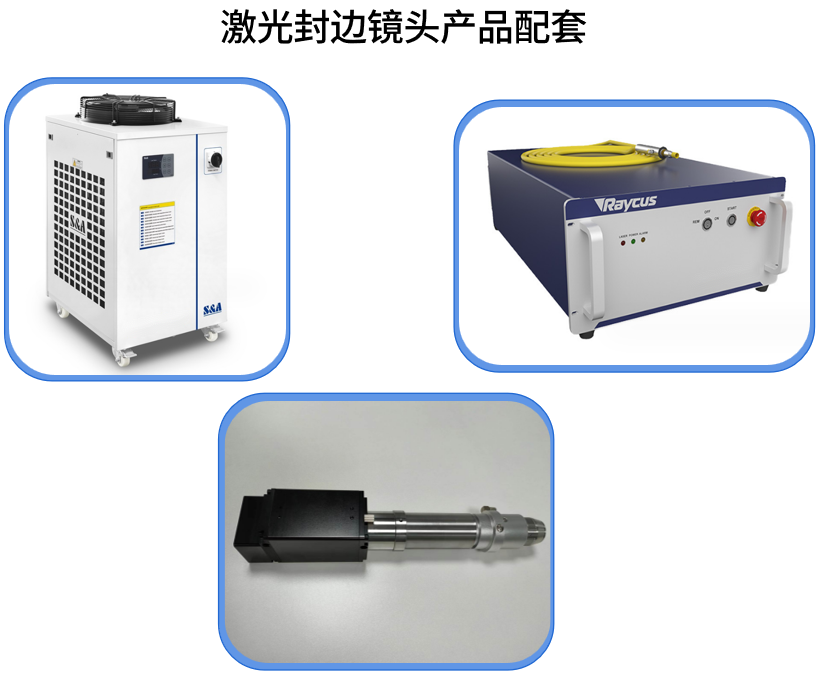

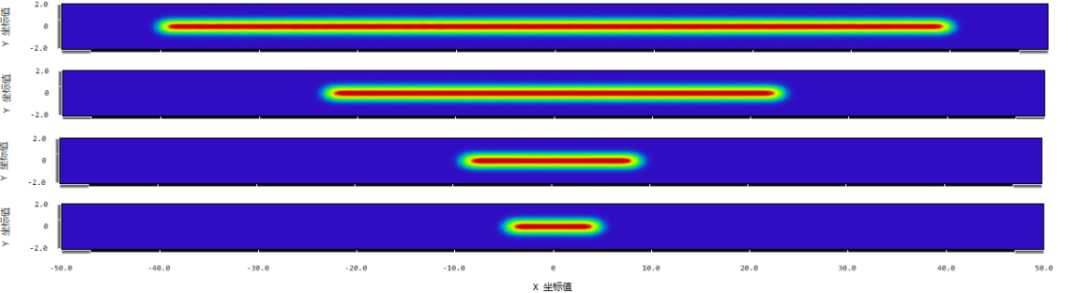

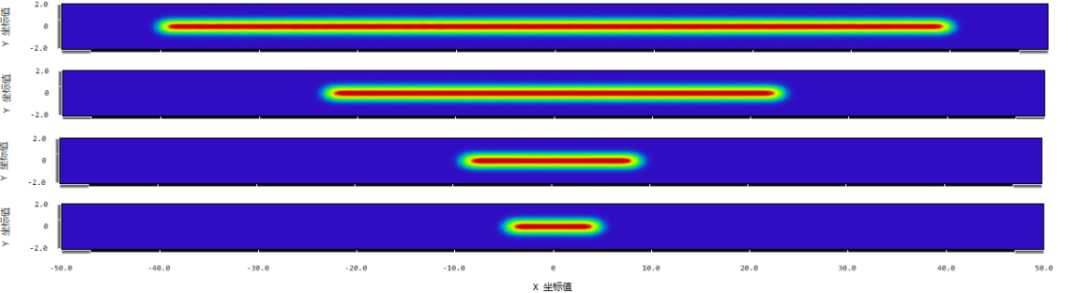

Currently, Jiamei ElectricAs a company that can provide professional optical design solutions and optical lens manufacturing production services, Zi (Shenzhen) Co., Ltd. has also brought new products——Adjustable laser edge banding lens, which can be matched according to the laser used, with a total length of approximately25cm, the matching band is900-1100nm, with a power range of1.5-6kw, working distance is400mm, can form an adjustable range within10-50mmThe linear light spots on both sides can achieve uniformity of the light spots90%In addition, the product also comes with a water-cooled structure, which can be used in conjunction with high-power water-cooled heat dissipation. The spot adjustment method can be adjusted with motor controlSuitable for furniture manufacturing edge banding, building material edge banding and other related laser edge banding industries.

Adjustable lens spot

The most intuitive change after edge banding of the board is that the internal structure and material are no longer visible from the side, and generally, the same colored edge banding is used for edge banding, making furniture with a more unified overall appearance more beautiful and generous.

When edge banding, adhesive is required between the edge banding strip and the board (straight strips are required, buckle strips are not required). This lateral reinforcement method will make the board less prone to cracking and enhance the overall quality and stability of the furniture.

All wooden furniture will face the problem of moisture, especially in areas with high humidity in the south. The result of moisture on the board is deformation, glue opening, etc., which can affect the use of furniture. And edge sealing can effectively prevent the board from getting damp.

Regardless of the environmental protection level of the board, it will release a certain amount of harmful substances such as formaldehyde. At this time, edge sealing can effectively slow down the release of formaldehyde. Although this kind of closure measure may seem to treat the symptoms rather than the root cause, it is always stronger than not doing it, and it is indeed effective.

Mei Light Electronics (Shenzhen) Co., Ltd.

Contact information: 0755-23097725 Email: info@mei-light.com Website: www.mei-light.com